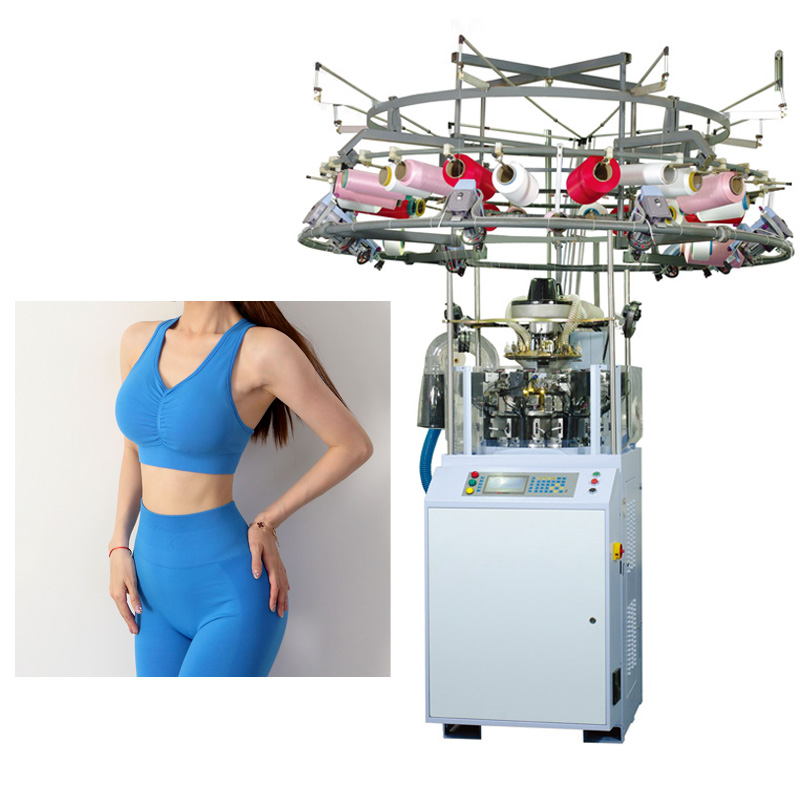

Bare Spandex Weaving Process

--The bare spandex fabrics produced by RFSM seamless underwear machine through intelligent and advanced spandex control system and combined with high needle distance knitting components, are featured at soft texture, delicate feeling, smoothness and brightness. The fabrics produced in combination with pure cotton, colored cotton, modal and other face yarns ensure good hygroscopicity and gas permeability, dangling and floating, with excellent elasticity and extension performance to maximize the

curvature of human body, and sculpt the sexy and charming beauty of women, which serves as future development trends of knitted underwear.

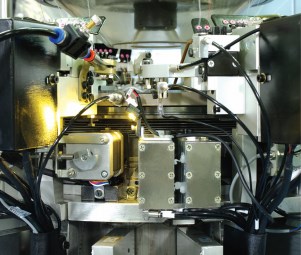

Intelligent Network of Electrical System

--Touch-type high-definition color display capacitive screen.

--Data bus control design make the circuit to be simple, clear, neat and beautiful.

--Unique test interface, electrical equipment management function and intuitive fault prompt information, to greatly reduce the failure shutdown rate.

--Convenient parameter modification function: the user can directly modify parameters such as speed and other parameters on the equipment computer.

--Simple and convenient zero operation and automatic zero correction function.

--Support work site protection for sudden power failure of power grid. Detect the grid voltage automatically, shut down automatically, and turn off the power automatically.

| Seamless Underwear Making Machine Technical Parameters | |

| Product Function | Applicable for weaving of various underwear, underpants, bras, sportswear, outerwear, etc. |

| Applicable Knitting Yarns | Cotton yarn, wool yarn, chemical fiber yarn, spandex covering yarn and blended yarn, etc. |

| Cylinder Diameter | 12-20 inches |

| Needle Gauge | 16-32 stitches/inch |

| Number of Feeds | 8 for every diamter |

| Yarnfinger | 8 pieces/feed |

| Actuator | 16-level, 2 pieces/feed |

| Stitch Cams | 1 per feed, controlled by stepping motor, the density of the same row is adjustable |

| Yarn Storage Device | 1 pieces/feed (optional 2 pieces/feed) |

| Constant Tension Yarn Feeder | 2, up to 10 |

| Broken Yarn Sensor | Total 43 sensors (51 sensors optional) |

| Compressed Air | Flow: 50L/min, Pressure: 0.6—0.7MPa |

| Suction Air | Flow :10M3/min, pressure: -0.8MPa |

| Net Weight | Approx. 700Kg |

| Maximum Speed | Max. 95RPM for RFSM20, max. 130RPM for RFSM30 |

| Lubrication | The lubrication amount of knitting needles, sinkers and selecting piece can be controlled |

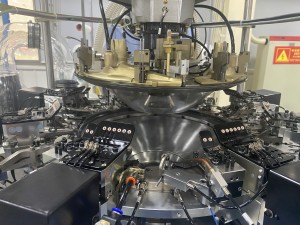

Detailed Images

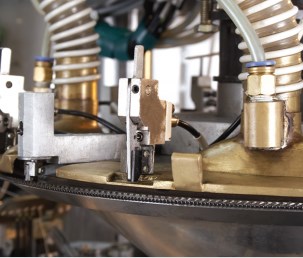

Automatic Dial Jacks

--The whole machine can be equipped with up to 64 yarn breakage sensors for real-time sensing the running status of each yarn. In case that the yarn is broken or entangled, stop signal is sent in time to effectively prevent the occurrence of fabric defects.

--The tying mechanism can automatically weave one or more elastic welt according to the process

requirements.

--One yarn clamp for each feed, of which feed No 2 and 6 double-layer clamps, which can automatically

clamp elastic yarns (e.g. spandex and colored yarn) and is conducive to continuous knitting.

Wide Adaptability of Process

--Two 16-level actuators each feed, for accurate control of each knitting needle twice.

--Each feed has 6 main yarnfingers, plus 2 colored yarnfingers for multi-color knitting. Among them, yarnfinger

1# and 2# have 3 positions, yarnfinger 3#, 7# and 8# have 2 positions, yarnfinger 4# and 5# have 4 positions, and yarnfinger 6# has as many as 6 positions.

--The stitch cams is controlled independently by a stepping motor with a conjugate cam. Each feed can change

the density of fabric in the same row quickly and uniformly realizing 3D function.

--The elastic yarn feeder can realize constant tension yarn feeding based on the requirements of fabric, and can automatically adjust the yarn feeding tension to ensure the elasticity requirements of each part of the fabric.

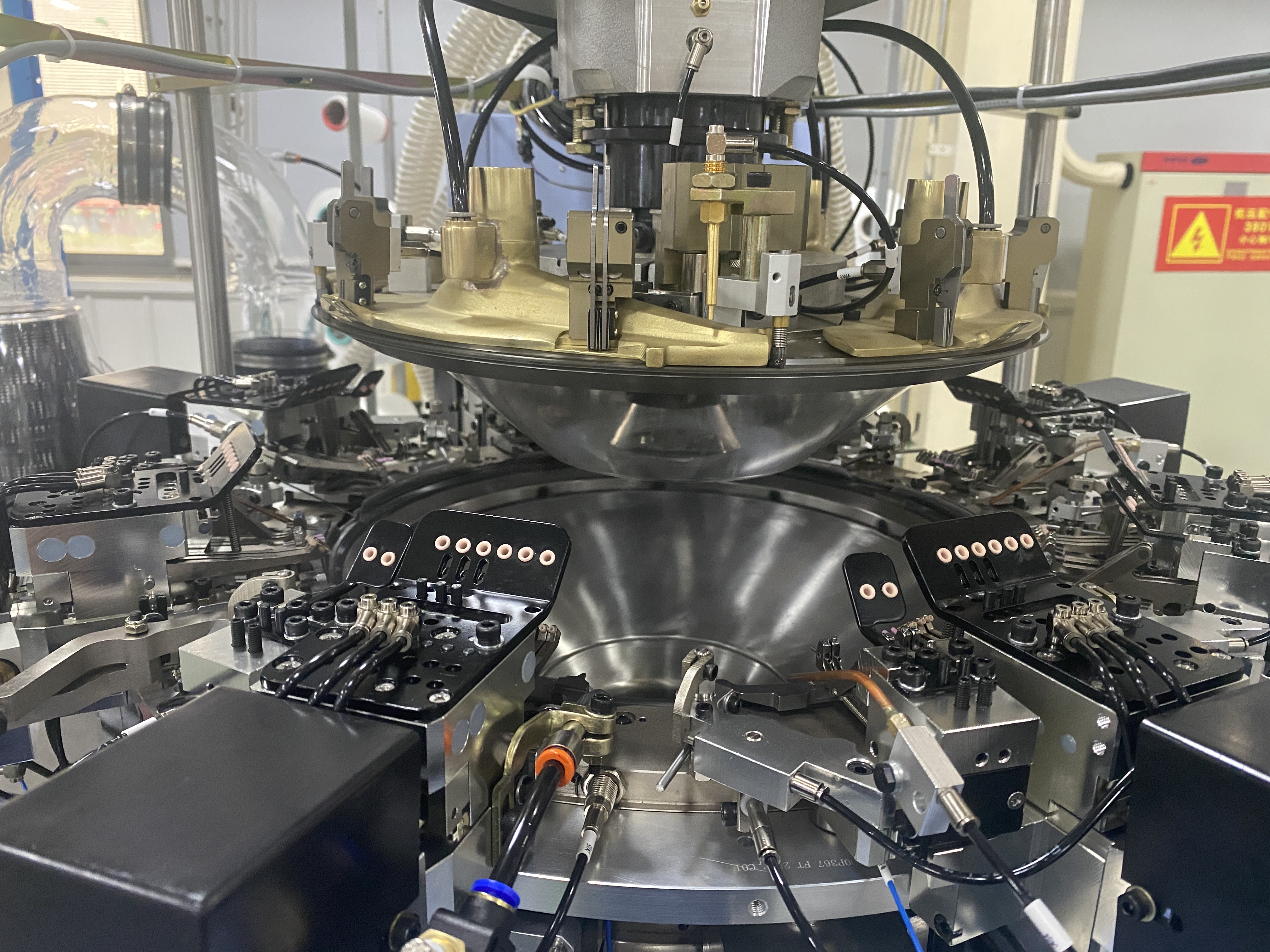

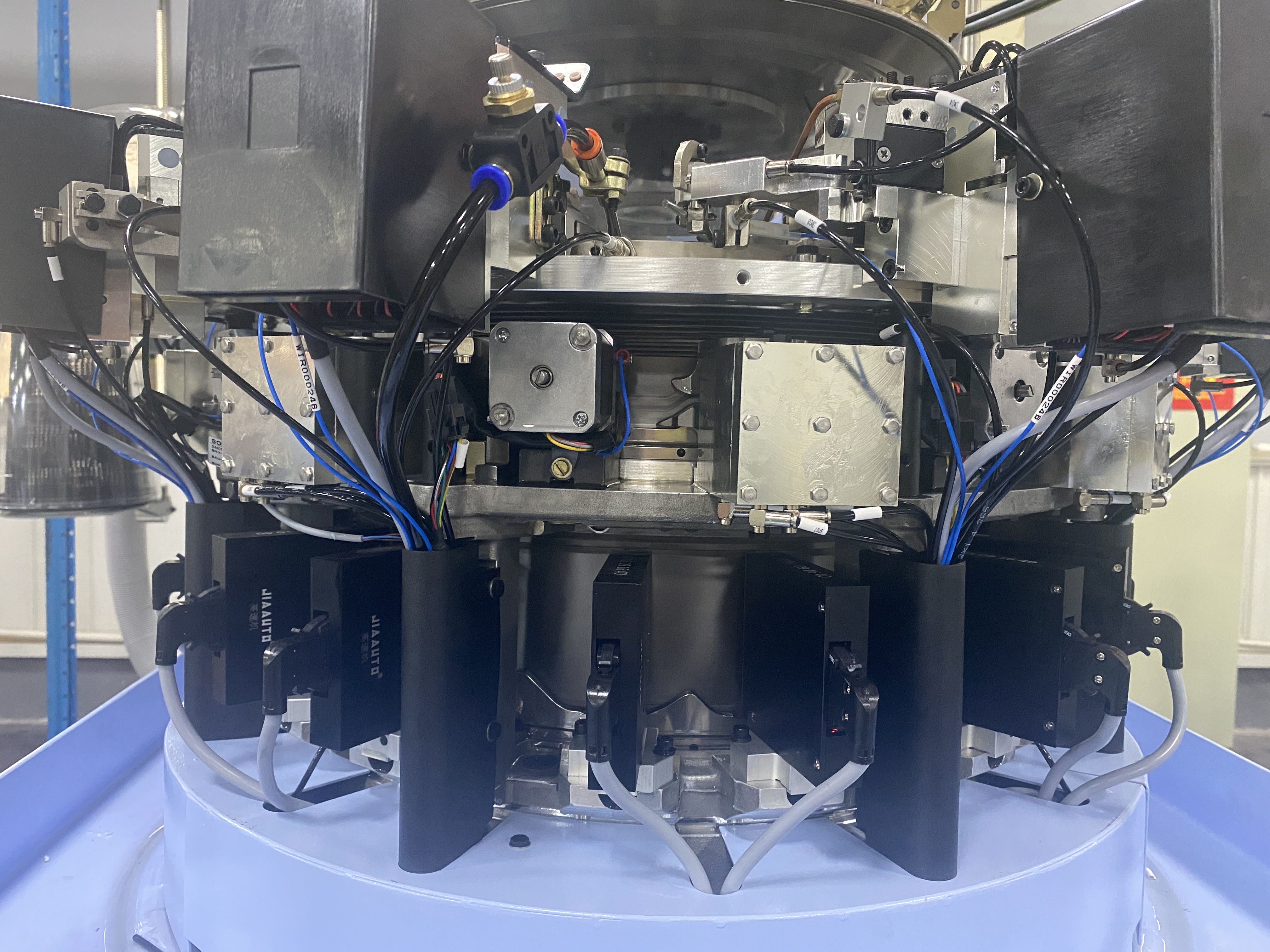

Optimized Design, Stable and Reliable

--The double-layer aluminum base is an integrated design, which adopts low-pressure casting, increases density of the molecular structure, and undergoes secondary solution heat treatment to ensure the relative position accuracy of knitting instrument, improving the working reliability of knitting instrument.

--The cylinder design adopts a split structure, featured at large space for discharging impurities,making it convenient for installation and maintenance.

--The key parts are tested by three-coordinates, and the accuracy is strictly controlled, so as to ensure the stability of the whole machine performance.

--The solenoid valve adopts integrated design, which is neat and convenient.

Pattern Preparation System

--The chain program software and pattern software are independent of each other and cooperate with each other, which can effectively reduce the programming time.

--The icon of chain program software is vivid, and the instructions are simple and easy to understand, making it convenient for customers in a short time.

--The pattern software is identical to the general drawing software, with simple and convenient operation, which supports direct import JPG, BMP and other formats, and the software performs color separation processing automatically.

--The knitting program is compatible with pattern making software of imported equipment.

Product Show

-

High Speed and Quality RB-6FTP-I Plain Terry an...

-

Automatic Good Price Sock Toe Sewing Machine So...

-

Fully Automatic RB-6FP Plain Competitive Sock K...

-

Low Pressure Industrial Electric Silent Screw A...

-

Soosan High Quality Fully Computerized Sock Mak...

-

Hot Sale Air Covered Polyester ACY Yarn Spandex...