Factory best selling Machines Used Socks - High Speed Automatic Sock Toe Linking Machine for Socks – Rainbowe Detail:

282 Two Motor Sock Toe Closing Machine

Product Description

1. Automatically lubricating nose device makes a longer performance life and a better working environment with low-noise.

2. Adopting automatically cutting device, the sutures will be cutting unified length.

3. Turnover yarn feeding device makes the yarn cleaning conveniently. Built-in automatic hoisting device is for conveying purpose, assure the socks’ planeness.

4. An optical fiber inductive time lapse function as yarn feeding makes it possible to set delay time according to the running speed, which reduces the waste of sutures substantially when sewing.

5. Adopting dual channel nose device, makes the sock sewed with fine flat seams, even similar as handsewer.

6. Adjusting the sewing density of socks is available with a renewal gear.

7. Point-contact touch screen computer control system makes it easy to handle.

8. There is an automatic hoisting device inside the second nose, which can be adjusted by computer. That comes to an easier and more accurately handling, and prevents the sutures from showing up.

Technical Parameters

| Production Capacity | 800 pairs/hour |

| Motor | 2 motors; 1 brushless motor, 1 stepper motor |

| Voltage | 220V |

| Freqency | 50HZ |

| Power | (Fan: 370W, Main process equipment: 220W) |

| Gross Weight | 120KGS |

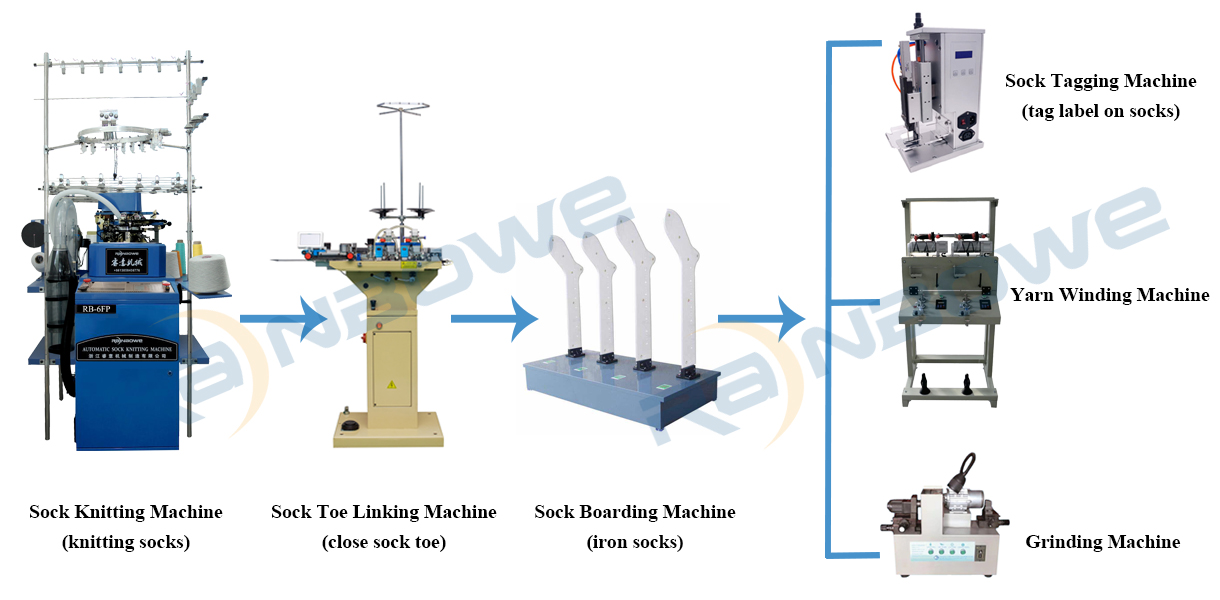

Sock Production Line

The finished socks from sock knitting machine is not completed, so sock toe linking machine is used to make toe closed.

There are several types can be offered: one linking motor 181, two linking motor 282, three linking motor 383, five linking motor 585, six linking motor 686. The more linking motor, the better linking effect.

One/ Two/ Three linking motor will be more popular to be purchased.

(Sock Tagging Machine, Yarn Winding Machine, Grinding Machine depends on your own needs)

Product detail pictures:

Related Product Guide:

To become the stage of realizing dreams of our employees! To build a happier, much more united and far more professional team! To reach a mutual profit of our clients, suppliers, the society and ourselves for Factory best selling Machines Used Socks - High Speed Automatic Sock Toe Linking Machine for Socks – Rainbowe, The product will supply to all over the world, such as: Tunisia, Dominica, Macedonia, With the effort to keep pace with world's trend, we'll always endeavor to meet customers' demands. If you want develop any other new items, we can customize them to suit your needs. If you feel interest in any of our products and solutions or want develop new merchandise, you should feel free to contact us. We are looking forward to forming successful business relationship with customers all over the world.

A good manufacturers, we have cooperated twice, good quality and good service attitude.