What is a dotting machine?

The dotting machine puts non-slip dots on the bottom of each sock or the palm of a glove. These dots prevent slipping, improving the overall comfort and safety of the wearer. The dotting machine uses advanced sensors and algorithms to accurately detect the size and shape of socks and gloves, ensuring precise and consistent dots on each product.

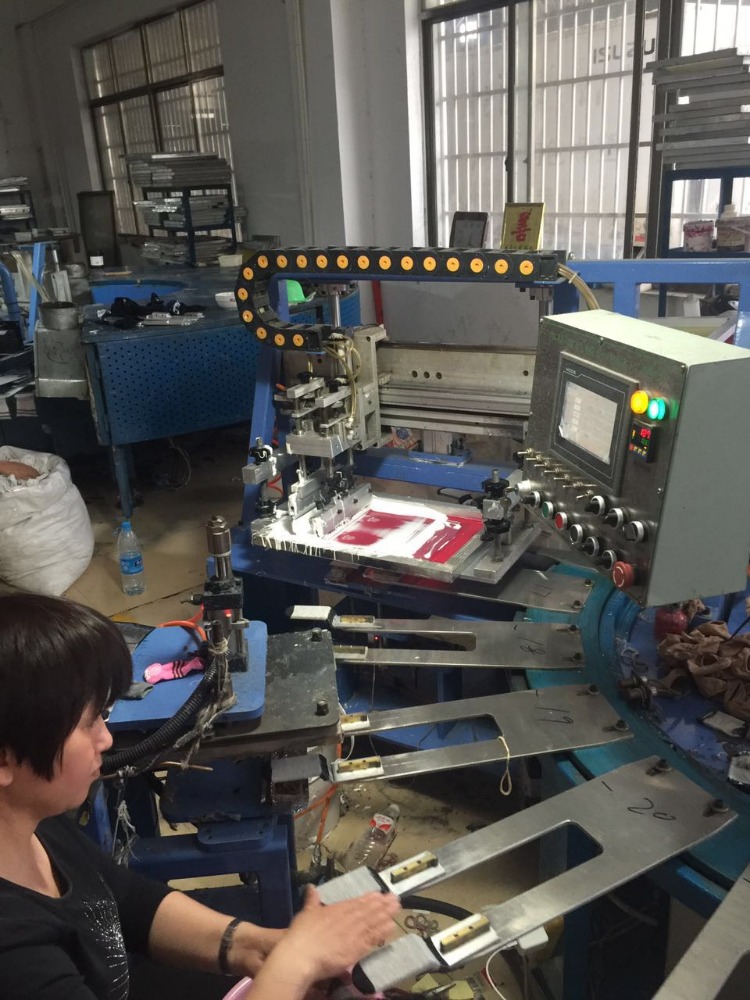

How does the dotting machine work?

The dotting machine works by removing a sock or glove from a feeder and using advanced sensors to detect the size and shape. The dotting machine then applies the anti-slip points to socks and gloves using a roller system. The entire process is automated, freeing up a lot of manpower and increasing production speed.

Benefits of using a dotting machine

1. Improve production speed

The 12-piece dotting machine can dot up to 600 pairs of socks in one hour. This means that manufacturers can produce more socks in a short period of time, thus meeting the increasing demand.

2. Consistency and precision

Dotting machines ensure precision and consistency in dotting each sock or glove. Advanced sensors and algorithms ensure that the dots are evenly distributed and accurately placed on each product, preventing any slippage during wear. This level of consistency cannot be achieved with traditional methods.

3. High cost performance

While the initial cost of purchasing a dotting machine may seem high, the long-term benefits are worth it. The machine reduces labor costs, requires minimal maintenance, and increases production speed, thereby increasing profits.

4. Improve product quality

Dotting machines ensure that the quality of socks and gloves is enhanced as each finished product is uniform and of high quality, giving manufacturers an edge in a competitive production industry.

Post time: Apr-21-2023